1800mm MAG welding robot for welding thick carbon steel

Characteristics

-Robot arm:

- Die casting process, aluminum arm ,Lighter and more flexible

- Internal wires and terminals of the robot are made by the top world famous brands: DYEDEN, TAIYO, the same as ABB and Fanuc

- Top Chinese brand of the controller,motor and reducer.

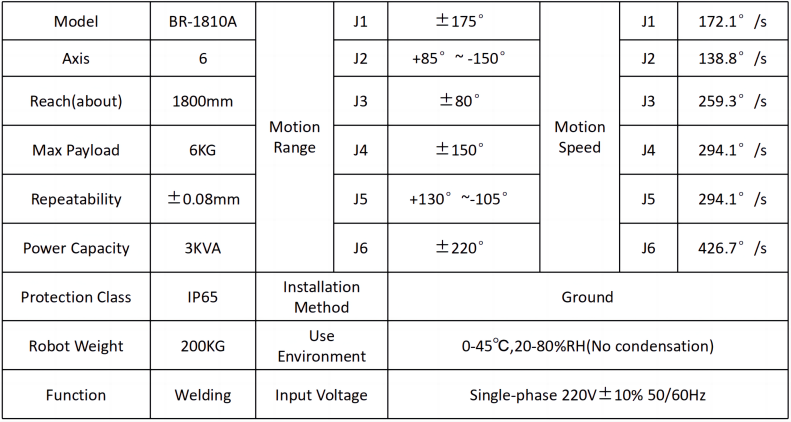

BR-1810 MIG welding robot parameters shows as below:

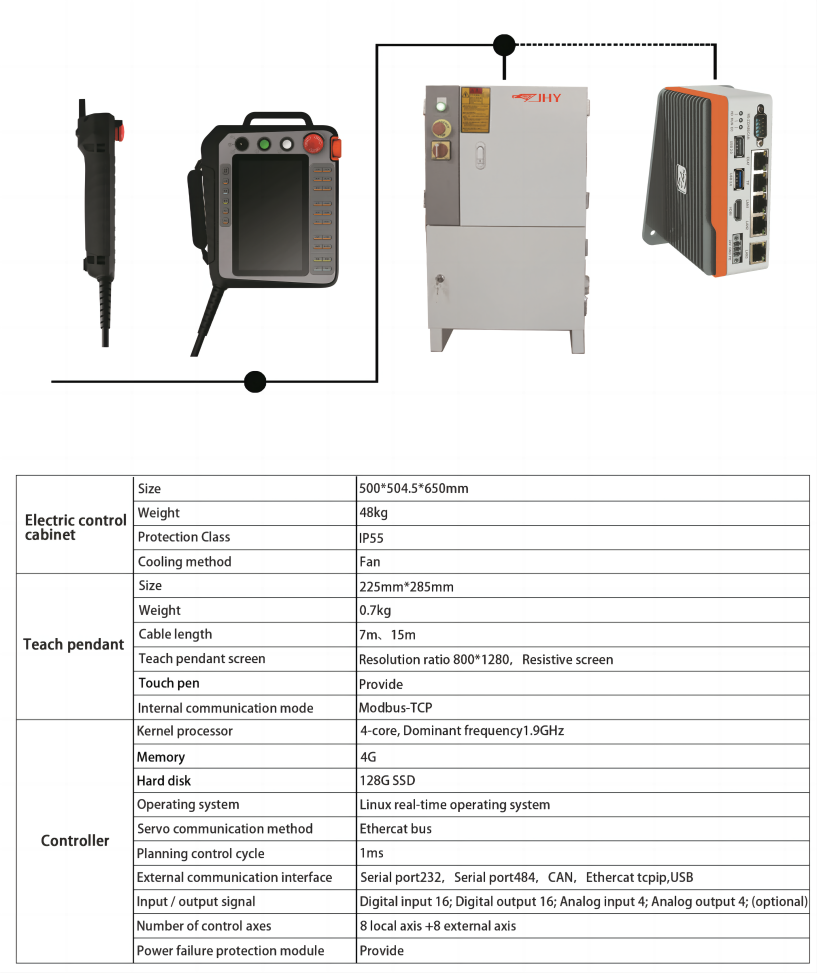

-JHY welding robot control system:

-Welding machine: :MEGMEET Artsen CM500

-

Digital Microprocessor Controlled Inverter Technology;

- Synergic control of MIG/MAG CO2 welding processes;

- Stable welding with stick-out lengths up to 30mm;

- Achieving stabilized vertical-up welding at 150A with flux-cored wire and 50m inter-connection cable set.

- Duty cycle 500A 100% @ 40°C

- Proven record in heavy industries since 2014;

- High tolerance against input voltage fluctuation (25%+/-);

- Protection of PCB and wire-feeder from vibration, collision, moisture, and salty air.

-Welding torch:

- Water-cooled with highly sensitive anti – collision device, greatly extend the service life of the torch

-Welding positioner & robot walking rail

- 1 axis,2 axis and 3 axis welding positioners are optional to choose. Payload and worktable size can be customized according to requirement.

- Robot walking rail can be made by customized according to customer’s requirement. length 3/6/9/12M.payload:500/1000KG

-The machine maintenance is simple and easy to operate, and the designed service life is more than 10 years

Paying Attention To Every Detail Makes JHY Robot Better

Write your message here and send it to us