6 axis Water-cooled 500A welding machine MIG welding robot arm

Characteristics

-Robot arm:

- Die casting process, aluminum arm ,Lighter and more flexible

- Internal wires and terminals of the robot are made by the top world famous brands: DYEDEN, TAIYO, the same as ABB and Fanuc

- Top Chinese brand of the controller,motor and reducer.

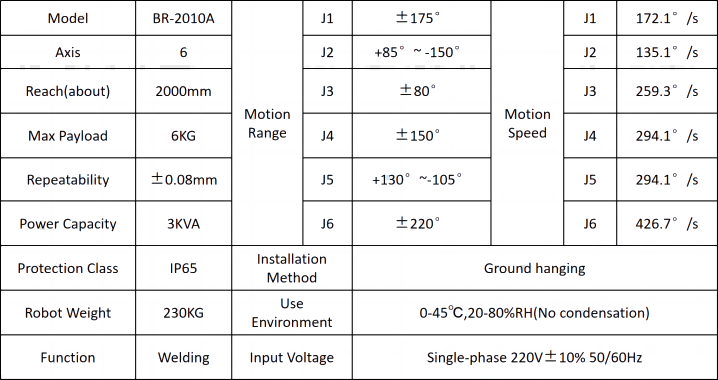

BR-2010 MIG welding robot parameters shows as below:

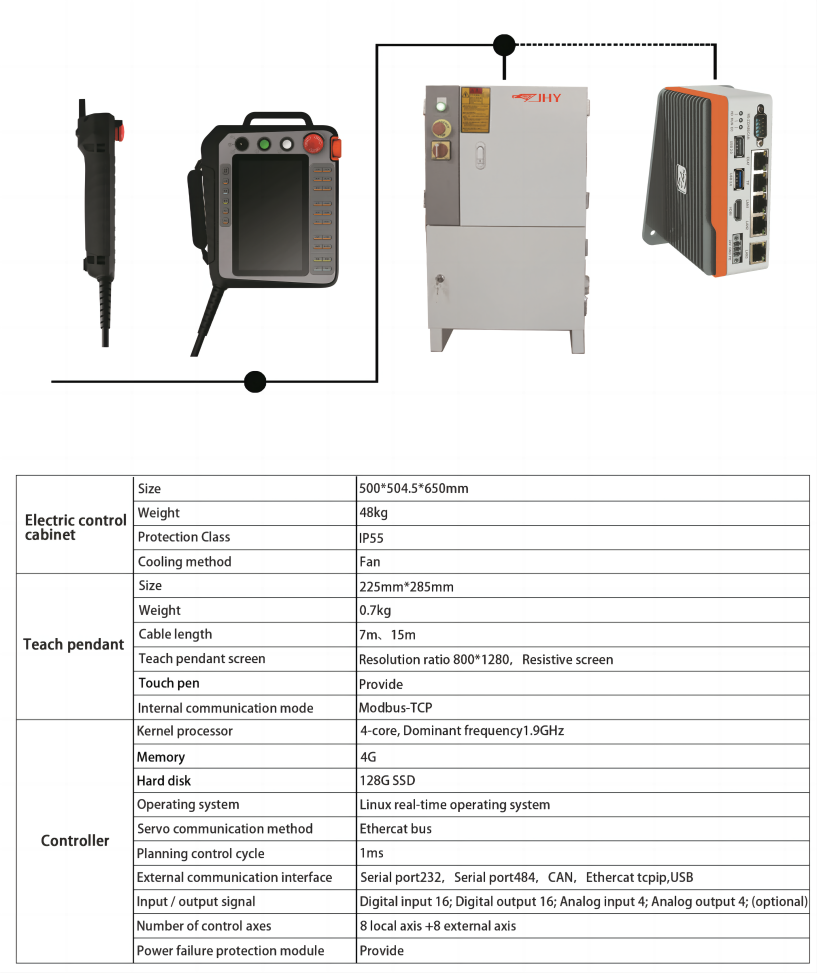

-JHY welding robot control system:

- It can support control up to 14 Axis linkage at the same time.

- The richest welding process package such as laser tracking, laser scanning, arc tracking, swing welding, laser welding

- Friendly interactive interface

- Excellent sports performance

- Easy to learn and operate

-Welding machine: :MEGMEET Artsen Pro500PR

-

The Artsen Pro series welding power source was developed based on the Artsen Plus series welder. It has met the demand for high-efficiency welding, especially for thick plates.

-

A power source of 500A 100% is available for the Artsen Pro series welder.

- With inverter technology of frequency as high as 100K HZ and high-speed sampling, Artsen Pro achieves precise control and is flexible with various welding characteristics.

- The Artsen Pro series brings LSA, a featured low-spatter welding process, as standard. Thunder Fusion is also available with Artsen Pro for the advanced short-arc pulse and double-pulse MIG/MAG.

- The Artsen Pro series welder meets high-quality welding of carbon steel, stainless steel, and aluminum alloys.

- Equipped with Constant Fusion, which allows wire-feeding speed at pulse mode to change automatically according to the stick-out length and keeps the penetration stabilized.

- Equipped with a USB port for upgrading, ensuring access to the most advanced welding process developed by MEGMEET and the most suitable welding software to face different welding conditions.

-Welding torch:

- Water-cooled with highly sensitive anti – collision device, greatly extend the service life of the torch

-Welding positioner & robot walking rail

- 1 axis,2 axis and 3 axis welding positioners are optional to choose. Payload and worktable size can be customized according to requirement.

- Robot walking rail can be made by customized according to customer’s requirement. length 3/6/9/12M.payload:500/1000KG

-The machine maintenance is simple and easy to operate, and the designed service life is more than 10 years

Paying Attention To Every Detail Makes JHY Robot Better

Write your message here and send it to us