Chinese High Quality Mig Welding Robot For Welding Stainless Steel

Robot Body

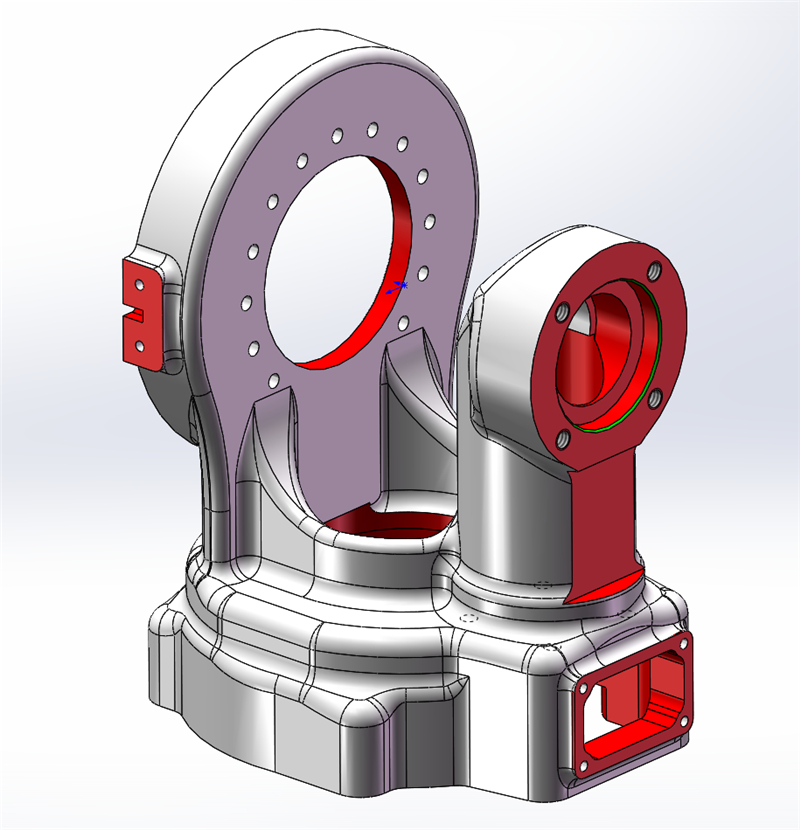

The JHY robot mainly changes in the die-casting process and detail design of the body, Our R& D team has made a lot of innovations in the design of the robot body, owning more than ten new invention patents.

For example, the sixth axis developed a high-precision transmission mechanism and designed reinforcing bars, also the sixth wheel output disc adopts gearless design,which greatly improved the accuracy and stability of the robot. Even if the welding torch works in a difficult attitude, it can still ensure the stability and without shaking. This point has been confirmed by our domestic customers.

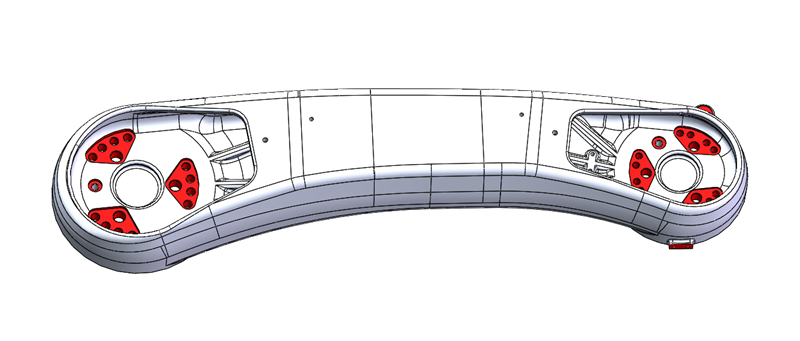

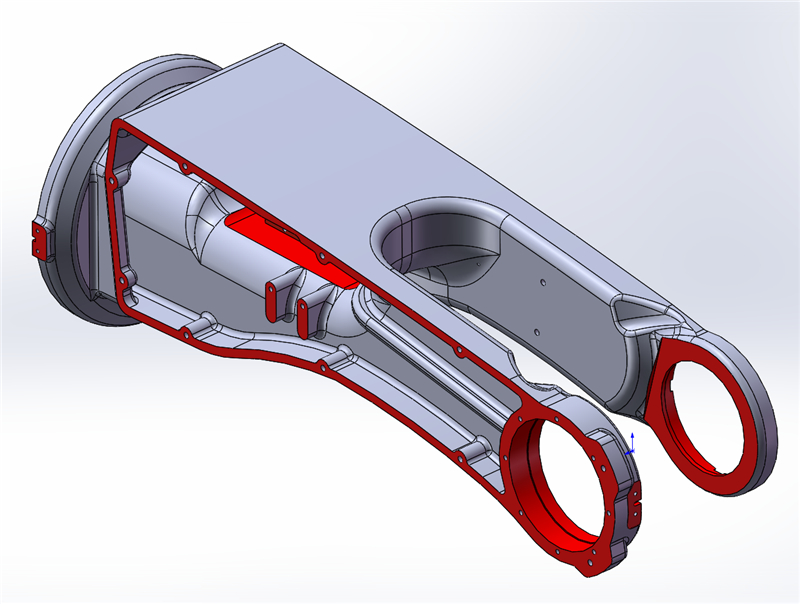

The robot body are produced by die-casting technology, this makes our robots with high density, lighter.Fore arm can be narrower and longer,The ratio between the upper arm and fore arm is closer to the golden ratio,so moving more flexible and faster.

Outline Design

The straight robot fore arm design is more simple and elegant.With a sense of design, more in line with the European market aesthetic.The robot body design has applied for a number of technical patents, the new robot body is more perfect.

Top Brand Of Wires

The internal wires and terminals of the robot are made by the top Japanese brands: DYEDEN, TAIYO, the same as ABB and Fanuc.

Terminal: Italian Yierma brand.

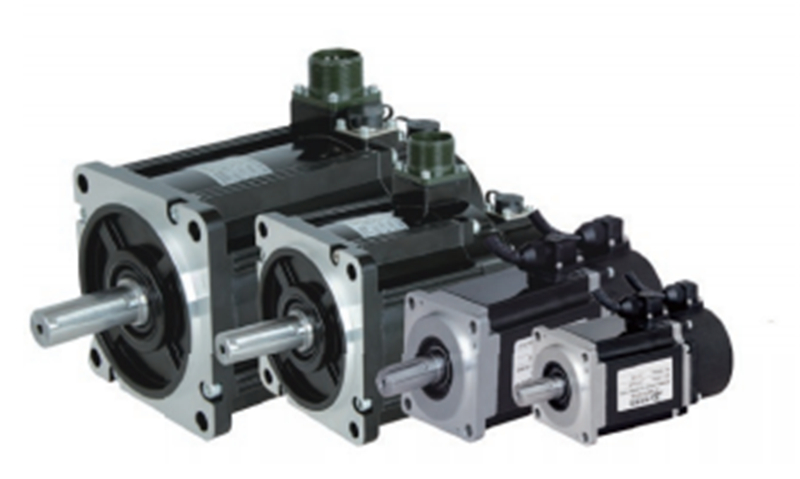

Leading Brands Of Servo Motor / Driver /Reducer

All of them adopt the leading brands in China. Each brand has been tested and investigated for a long time before the final decision is made, so as to ensure that these brands are suitable for the use of our robots and that their quality and performance are stable and reliable.

The J1 and J2 axis adopt the design of three eccentric shafts with a torque up to 65 N.m which reduces the wear of the gear and increases the service life of the reducer. JHY robot J1 and J3 axis reducers are currently the highest configuration in China.

About the servo motor, Now we use the 3kw motor at most for robots.

For 1.8m and 2m robots, the driving force required for the 1st and 2nd axes is greater, and the requirements for the motor power are also higher.

The high-precision and multi-specification motors can fully meet the applications demand for our robot.

3yrs/7500h Maintenance-Free

Maintenance is simple, customers themselves can easily operate.

Other Patents And Designs

6-axis secondary transmission Changed to two belt connections, increased the transmission ratio, and solved the problem of 6- axis moving too fast and inaccurate. The sixth-axis output disc is designed without gears, with high-precision transmission mechanism, which improves the movement accuracy of the sixth axis... At the moment we have more than 30 related patents for the welding robot.

Video

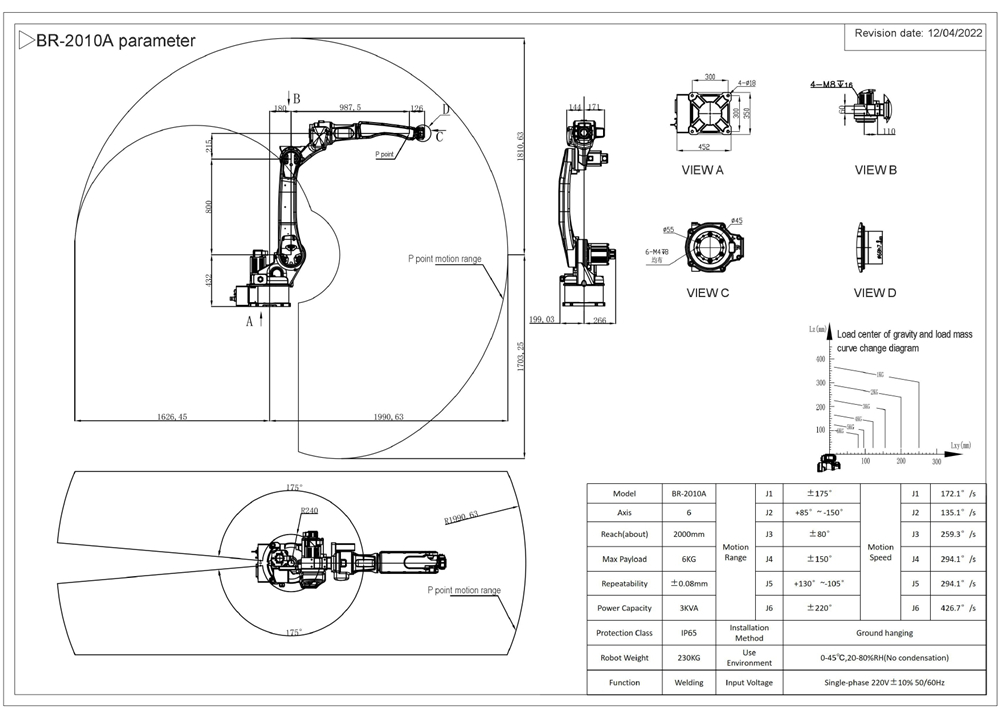

Parameters

| Model | BR-2010A | Motion Range | J1 | ±175° | Motion Speed | J1 | 172.1°/s |

| Axis | 6 | J2 | +85°~ -150° | J2 | 135.1°/s | ||

| Reach(about) | 2000mm | J3 | ±80° | J3 | 259.3°/s | ||

| Max Payload | 6KG | J4 | ±150° | J4 | 294.1°/s | ||

| Repeatability | ±0.08mm | J5 | +130°~-105° | J5 | 294.1°/s | ||

| Power Capacity | 3KVA | J6 | ±220° | J6 | 426.7°/s | ||

| Protection Class | IP65 | Installation Method | Ground hanging | ||||

| Robot Weight | 230KG | Use Environment | 0-45℃,20-80%RH(No condensation) | ||||

| Function | Welding | Input Voltage | Single-phase 220V±10% 50/60Hz | ||||