Intelligent Welding Robots Open A New Era In The Steel Structure Industry

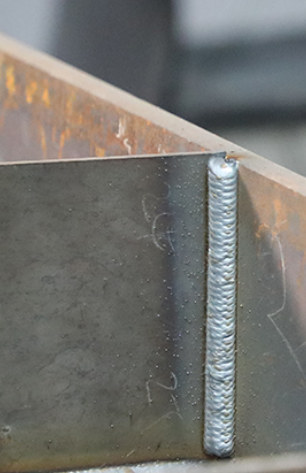

As an important means of steel body connection, welding has been widely used in the steel structure industry, and the application of intelligent welding robot in the steel structure scene has been gradually promoted.

From the perspective of application scenarios, welding robots have been applied in construction, steel, bridge, electric power, petrochemical, automobile manufacturing and other industries. At present, head steel structure manufacturers are gradually promoting the application of welding robots to improve production efficiency.

According to the current demand, the potential market of steel structure welding robot in 22 years may reach nearly 20 billion level.

We believe that the market space of ten billion level steel structure intelligent welding robot is gradually opening, and intelligent solutions are expected to further penetrate. It is suggested to pay attention to the manufacturers who have accumulated the core hardware and software technology of intelligent welding robot and can be the first to achieve scene iteration.

Intelligent trend evolution, intelligent welding robot scheme continues to land

In the steel structure industry, the trend of welding robot intelligence continues to evolve.

According to the degree of intelligence from low to high, the welding robot can be divided into teaching reproduction type, offline programming type, autonomous programming type.

The teaching type need human input to complete all kinds of movement, process information, and repeated by the robot memory, offline programming by sensors for the robot content appropriate feedback control, autonomous programming welding robot is based on this further joined the decision and planning ability, can use the computer processing sensing results and the welding task planning.

We believe that in a variety of welding robot types, welding robots with a high degree of intelligence can help to effectively reduce the labor cost input, and is an important direction for the development of welding robots.

Intelligent welding robots need a variety of hardware and software technologies, and the importance of core technology accumulation is increasing

Compared with the traditional welding robot, the key technology of intelligent welding robot puts forward higher requirements for intelligent related technologies, mainly including offline programming, visual positioning, motion simulation, path planning, motion control, weld tracking, etc.

In the existing industry practice, the more advanced intelligent welding robot through visual modules, programming software, AI technology to achieve simple teaching and automatic programming.

The sensor can sense the surrounding environment, and realize the workpiece positioning, weld tracking and other functions.

Welding software can quickly program to generate welding paths, reducing the complexity of teaching and the threshold of use.

We believe that with the gradual release of the demand for intelligent welding robots, the importance or further improvement of core software and hardware technologies such as sensing, planning and control, manufacturers with relevant technology accumulation are expected to take the lead in creating landing intelligent welding robot solutions.

Focus on the accumulation of full-stack software and hardware technology and the landing of industrial scenarios

As the trend of welding robot intelligence continues to evolve, we believe that manufacturers with core capabilities are expected to fully benefit from the development trend of intelligence.

Core capabilities include: 1) global software capability: sensing / planning / control algorithm development capability; 2) full stack software capability: robot algorithm / operating system / middleware; 3) software and hardware integration capability: embedded software / intelligent hardware development capability; 4) hardware production capability.

We believe that manufacturers with the above capabilities are expected to take the lead in creating intelligent welding robot solutions that can be landed, and can take the lead in landing intelligent welding robot solutions or continue to accelerate the iteration in use, the product power is further improved, and the first-mover advantage is expected to continue to expand.

Post time: Nov-16-2023