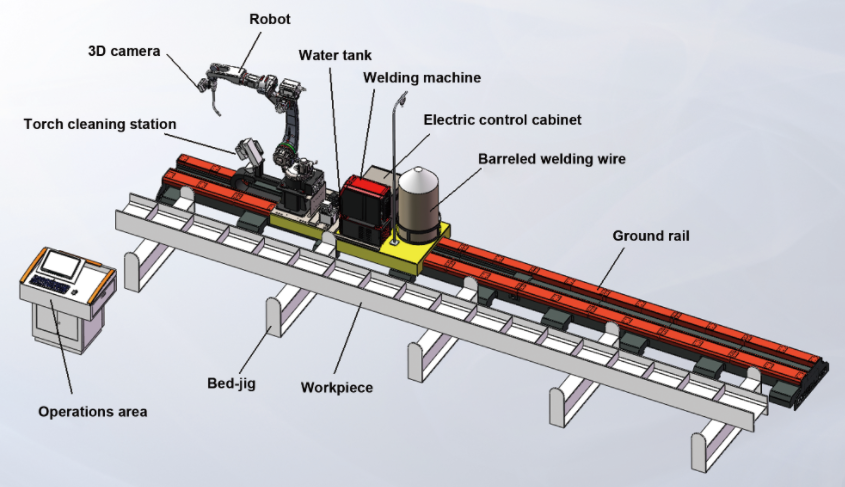

1.Equipment Overview

The cantilever intelligent welding workstation is mainly used for robot automatic welding of all kinds of steel structure corner welds, and the workstation meets the welding requirements of H steel structure, diaphragm plate, and structural parts of mechanical equipment base.

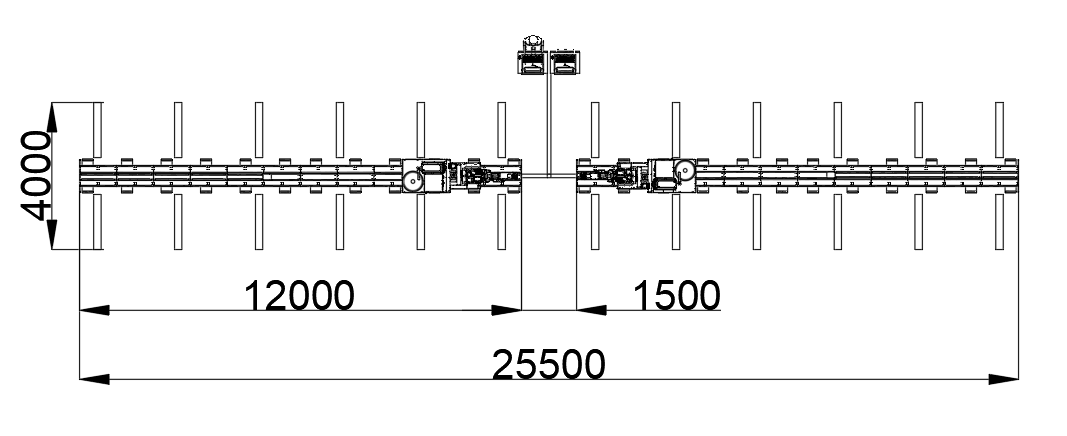

The total length of the ground rail is 12 meters, and the effective welding width of the robot arm is 1.2 meters.Install the ground rails according to the workshop layout and production process; weld seam form: flat angle weld, flat shaped zigzag line weld, vertical fillet weld, and corner welding (excluding multiple layers welding ).

Steel structure products: including H-shaped steel column, roof beam, crane beam (driving rail beam), mechanical equipment base structural parts and other relatively steel structure products.

1.1.Summary Of Workstation Functions

1) The design drawings of the workstation have been repeated demonstration and simulation design. The strength of each component is reliable, and the assembly and maintenance is convenient. On the premise of ensuring the function, the beautiful appearance is guaranteed.

2) All components of the workstation equipment are provided by well-known manufacturers in the industry (see the configuration list for details). The quality of all processed parts has been strictly checked, up to standard strength, superior performance and smooth movement.

3) The parts and instruments of workstation equipment and measures of all drawings shall adopt national standard sheet (GB) ; the design, manufacture and materials of all instruments shall comply with ISO and IEC standards or other equivalent standards.

4) The parts of the workstation are made of high quality materials, and the mechanical and electrical components selected are high quality, mature and reliable series products.

5) The front end of the robot has an anti-collision sensor, which can be protected in time in case of collision. At the same time, the automatic gun cutting system can be configured according to the requirements.

6) Intelligent welding functions such as workstation parametric modeling, three-dimensional digital-analog drive, intelligent planning welding path, laser vision sensor photo correction path, alarm beyond the limit deviation range, matching parameters and automatic creation of process library welding program.

7) Workstation working process:

2.JHY Intelligent Operating System

JHY independently develop the system, its main function is to deeply integrate the welding process, import the 3D model, accurately locate the whole workpiece weld through the visual system, and automatically generate the welding program according to the actual outline

The software is deployed on the PC system, which can be placed in any place, that means can be controlled remotely by no wiring, the equipment can be directly operated in the office for welding.

3.Equipment List

|

1 set of ground rail welding workstation |

||||||

|

NO. |

Item |

Name |

Unit |

QTY |

Brand |

Remark |

|

1 |

Robot |

Welding Robot |

set |

1 |

JHY |

BR-2010A Pro |

|

2 |

Customized Cables |

set |

1 |

JHY |

||

|

3 |

Control Cabinet |

set |

1 |

JHY |

||

|

4 |

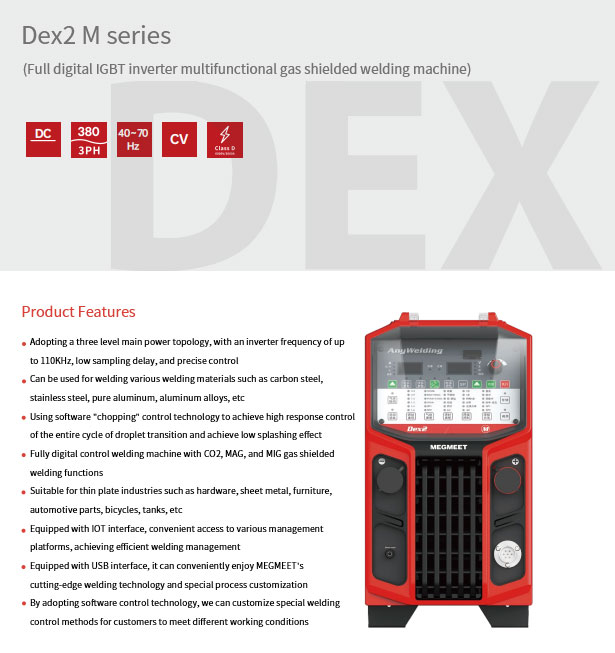

Welder Machine |

Digital Pulse Welding Machine |

set |

1 |

Megmeet |

DEX2 500MPR |

|

5 |

Customized Cables |

set |

1 |

Megmeet |

||

|

6 |

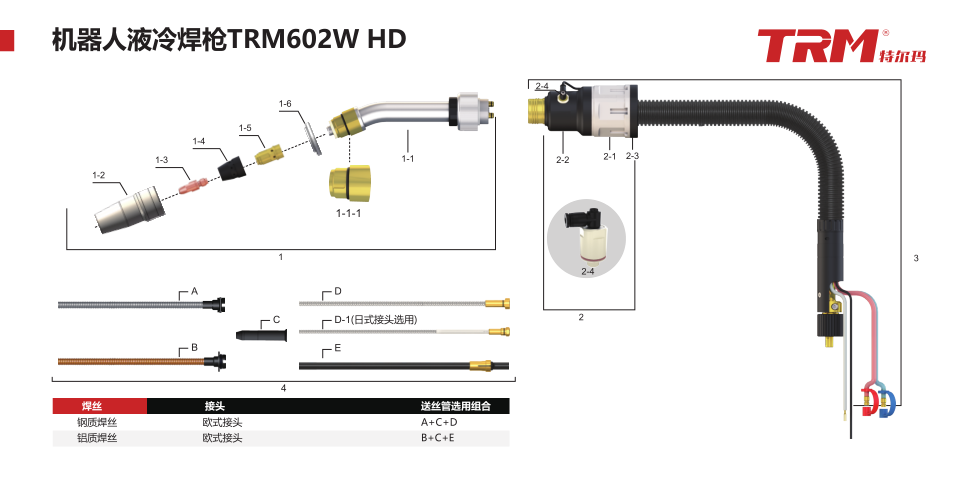

Welding Torch with Water Cooling |

set |

1 |

TRM |

TRM602W HD-45L | |

|

7 |

Water Tank |

set |

1 |

Megmeet |

||

|

8 |

Torch Clean Station |

set |

1 |

BeiJing JinYu |

||

|

9 |

Move System |

Fully Enclosed Ground Rail |

set |

1 |

JHY |

BR6100A-12 |

|

10 |

Servo External Axis |

set |

1 |

JHY |

2.2kw Driver |

|

|

11 |

Servo Motor |

set |

1 |

JHY |

130/2.2kw |

|

|

12 |

Customized Cables |

set |

1 |

JHY |

||

|

13 |

Positioner |

Single Axis Positioner |

set |

1 |

JHY |

JHY4300A-120 |

|

14 |

Servo External Axis |

set |

1 |

JHY |

5.4kw Driver |

|

|

15 |

Servo Motor |

set |

1 |

JHY |

180/5.4kw |

|

|

16 |

Customized Cables |

set |

1 |

JHY |

||

|

17 |

Visual System |

BCW600P |

set |

1 |

Mech-Mind |

Composite Camera |

|

18 |

Software |

Operating PC |

set |

1 |

JHY |

|

|

19 |

Intelligent Operating System |

set |

1 |

Bochu |

||

4.Equipment Configuration

4.1Basic Components Of Welding Robot System:

4.2 Layout Of Welding Workstation:

4.3 Model Of Welding Robot :BR-2010A Pro

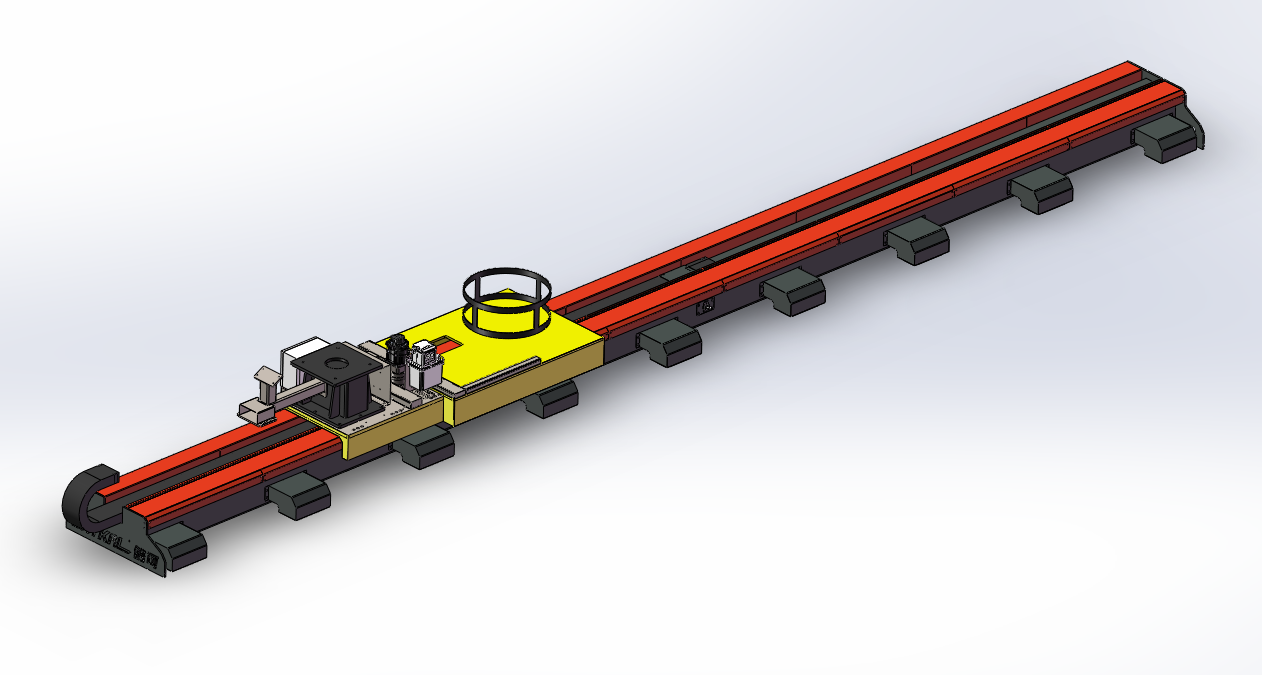

4.4 12 Meters Ground Rail

Ground Rail Parameters

|

Name |

Ground rail System |

Installation Environment |

Temperature |

-10-45℃ |

|

|

Model |

BR6100A-12 |

Humidity |

20-80% |

||

|

Structure |

Ground rail single machine |

Vibration |

Below 4.9m/s2 |

||

|

Max payload |

1000KG |

Others |

No flammable or corrosive gases or liquids are allowed, and water, oil, etc. are not involved. High strength interference sources should not be approached | ||

|

Positioning accuracy |

±0.05mm |

||||

|

Axis |

1 |

||||

|

Length of X-axis track |

12 Meters |

Maximum moving speed |

33m/min |

||

4.5 Welding Power Supply

MEGMEET DEX2 500MPR

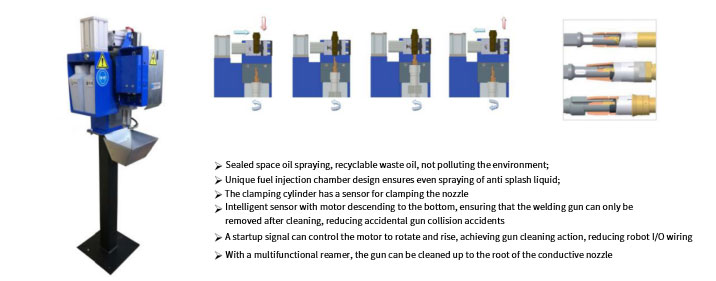

4.6 Torch Cleaning Station

4.7 Water-Cooled Welding Torch

4.8 Laser Vision Sensor

Post time: Oct-07-2024